Creating the perfect product is always a challenge

That is why Brandhoff Engineering is here to help you navigate your uncertainties.

Let us design better products together

Product development, all the way from idea to market

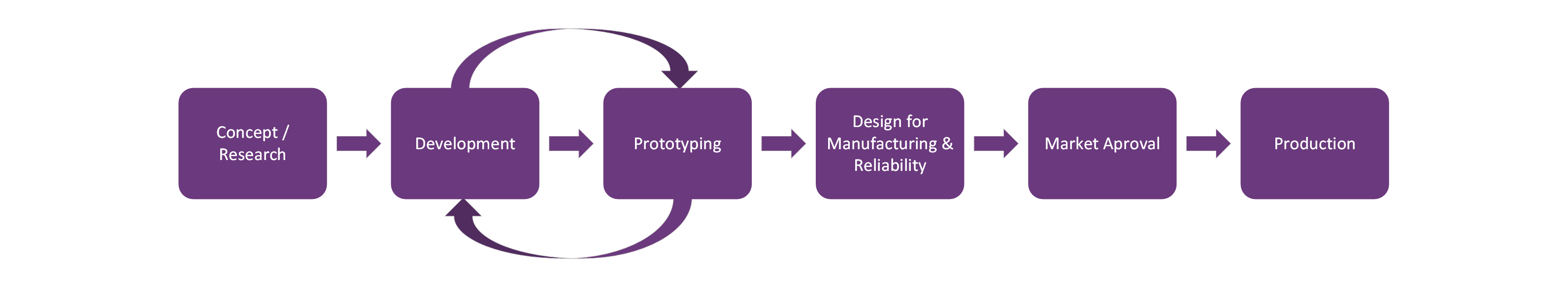

We provide assistance to our customers along the entire journey from product idea to mass production.

Whether you require experienced insights for specific tasks or comprehensive start-to-finish product development services, we are happy to help you in a manner that suits your needs and capabilities.

Concept

During the concept phase, we validate the technical feasibility of your product idea by utilizing a combination of industry expertise, in-depth simulation, and real-life experiments.

This process serves to demonstrate how your goal can be achieved within its economical, ergonomic, and technical constraints.

Based on these results, we develop a plan for the upcoming engineering project and assist you in drafting the requirements specification that will drive further development.

The earlier that Brandhoff Engineering is involved in your project, the better we can contribute to a successful product development. Rest assured, we guarantee confidentiality and non-disclosure to protect your product from competitors.

Development

Successful product development relies on the strong interaction between the different engineering domains. To ensure this, we offer a range of design capabilities under one roof to bring even the most complex products to life. These include among others:

- Precision analog electronics

- Digital/mixed-signal electronics

- Power electronics

- Sensors and sensor systems

- Actuators and motors

- Mechanical components

- Optics

- UI elements and controls

- Enclosures

Throughout the development process, we adhere to up-to-date standards, established techniques, and cutting-edge designs to deliver a safe, reliable, and market-ready product to you.

Prototyping

During the engineering process, prototypes are used at various points to verify the suitability of the product under development. This includes conducting experiments during the concept phase, creating functional prototypes during development, and designing ergonomic and user-experience prototypes for in-house and field testing and evaluating all of these prototypes.

Brandhoff Engineering utilizes modern prototyping techniques such as CNC-Milling, 3D printing, and other rapid prototyping methods to quickly build prototypes and iterate on ideas and development results as early as possible.

The feedback from the prototyping phase is used to iteratively refine the product before mass production begins. For a typical product it takes about four development-prototyping iterations before the final, ready-for mass production product, however this may change depending on the complexity of the product.

Prototyping is important not only from an engineering standpoint, but also makes sense economically. The earlier a bug in a product is identified, the more cost-effective the fix will be.

Design for Manufacturing & Reliability

We conduct a thorough analysis of your product from a production perspective, identifying potential pitfalls and inefficiencies during manufacturing. This process helps to enhance reliability and ensures a seamless scale-up to larger production quantities.

Designs are optimized based on established industry guidelines and internal expertise, allowing for proactive measures to prevent any device failures at the customer level. Furthermore, difficult-to-obtain components can possibly be eliminated from the design to increase resilience against supply chain disruptions.

Market Approval

The European Union and international market approval and regulatory affairs are often underestimated by new companies trying to bring a product to market. Brandhoff Engineering will support you through the entire regulatory process and ensure that you are market-ready. We are well versed in Standards, laws, and regulations, and can provide in-depth knowledge of their application. Additionally, we can help you perform proper risk analysis and self-certification where applicable.

The preparation for CE - Declaration of Conformity already begins early in the development process. We can assist you in preparing the comprehensive internal technical documentation necessary and guide you and your product through all mandatory test laboratories, including those for electrical safety, EMC/EMI compliance, and any other requirements to ensure your device is market-ready.

Production

We offer comprehensive manufacturing support services, which include preparing your product for mass production, providing the necessary documentation for approaching potential production facilities, and assisting in finding an appropriate production partner.

Additionally, we manage production surveillance and quality assurance for you during the production process. If needed, we can offer redesigns and design optimization throughout the production run, and closely monitor your product's production from the initial unit production to phase-out.

Contact us today

If you have any questions, are unsure whether or not we can help you or already know that you want to work with us, feel free to contact us below